Barrel Electronics

The barrel electronics section of this manual contains descriptions

of the barrel electronics for the DEIMOS Spectrograph. It corresponds to the

Barrel Electronics tab in the electronics schematics binder.

Overall

Block Diagram,

EL-3001

EL-3001

Schematic:

schematics/SERVO.sch.pdf

Page last updated: June 17, 2003

Jump to: Sheet 2, sheet 3

This

3 sheet schematic gives a general overview of the control electronics on the

rotating portion of the DEIMOS instrument. (The Cradle

Electronics section of this manual gives the same kind of information

for the non-rotating part of the instrument.) The first sheet shows the overall

interconnections and communications between the various components of the

system. Sheet 2 illustrates the expansion I/O connections for Galil Controller

#1 and sheet 3 illustrates the expansion I/O connections for Galil Controller

#2.

Sheet 1:

Simplified Drawing

Photos

|

Galil panel #1

|

Galil panel #1 and Lamp interlock box

|

Galil panel #2

|

Galil panel #2 and Ion Pump controllers

|

|

|

|

|

|

|

|

|

|

|

|

Lantronix, A2S convertor, Data Logger, and SCSI-to-Fiber

convertor

|

Orange circuit over temperature control and HP data

logger sensor junction box

|

Lantronix Time-on Relay and Slitmask Barcode Supply

|

|

|

|

|

|

|

|

|

Lantronix Terminal Server: (see Bay

3 photo)

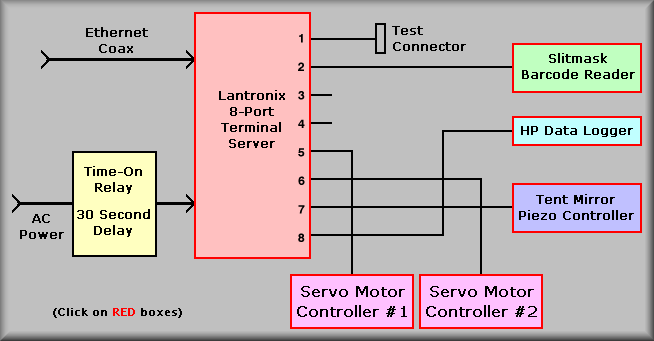

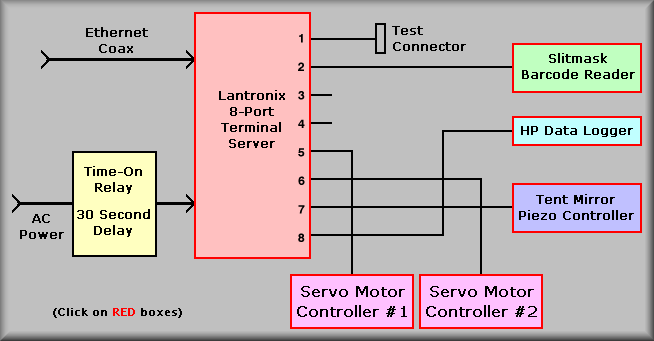

This sheet shows all of the components of the electronics mounted in the electronics

ring except the CCD controllers. At the top of the drawing are the communication

lines of the instrument. The block in the top left represents the Lantronix

ETS8P terminal server. The terminal server supplies 8 serial port using RJ-45

connectors. The ports are allocated as follows:

- Test port - left open for direct connection to the Lantronix for configuration.

- Slitmask bar code scanner.

- <Not assigned>

- <Not assigned>

- Galil controller #1

- Galil controller #2

- Piezo controller. (Tent Mirror control)

- HP Data Logger. (Temperature logging)

A race condition can exist when power is applied to the instrument. The Lantronix

box can become confused if it receives 'garbage' characters on it's serial ports

while it is powering up. To insure that the Lantronix power is the last box

to come on, a Potter & Brumfield 1.8 to 180 second 'Time-On' delay relay

is wired in series with the AC power for the box. The relay and socket are located

on the back of the Lantronix mounting plate and the delay is set to about 60

seconds.

(Back to Top)

Bar Code Scanner:

Slitmask Barcode Reader

To the right of the Lantronix box are boxes that represent the bar code reader,

the data logger, and the piezo controller. The Symbol Technologies LS 1220 bar

code reader for the slitmask system is mounted inside the instrument on a solid

mount that allows it to scan the bar-codes affixed to the individual slitmasks.

This unit is powered by an AC wall adapter that is located at the back of the

rack containing the Lantronix box. The adapter is held in place with a with

metal strap. Though the power is always on, the beam is

turned off and on via software and currently is planned only to be on when the

slitmasks are initially inserted into the cassette. The scanner is a serial

device and is connected to Lantronix port 2.

(Back to Top)

HP Data Logger: (see Bay

3 photo)

Extra info:

HP Data logger

Beneath the barcode scanner is the HP

Model 34970A Data Logger. This box can control as many as 30 RTD type sensors

(R.T.D. Company, RS2P-463). The DEIMOS instrument has 27 sensors wired in. The

data is read once every ten minutes and archived on the data

taking computer. The idea is to keep record of the temperatures at various

points on the structure that can be examined to see how the instrument acclimates

to the mountain top and also as a record in case of any unexpected behavior

of the instrument. At this time, there are no plans to display the inputs but

a process can be set up to dump the data to a window if necessary.

(Back to Top)

The Physik Instrumente P-845 Piezo Controller:

Piezo Controller

The Piezo control box is again a serial device and it communicates via Lantronix

port 7. It controls the position of the tent mirror which is part of the flexure

compensation system. The tent mirror can steer the light beam to keep the image

on the detector steady as the instrument rotates and flexes. The

actuator is a self contained unit that consists of a piezo element and a strain

gauge. It has a stroke of 90 microns and

can be controlled either via the communications port or front panel controls.

The unit must always be set for remote operation. The operation manual

and user guide accompany the outside vendor manuals bundle.

Front panel

switch settings

PDF version of Operating

Manual

Please note: the controller box

MUST be powered down before connecting or disconnecting the actuator.

(Back to Top)

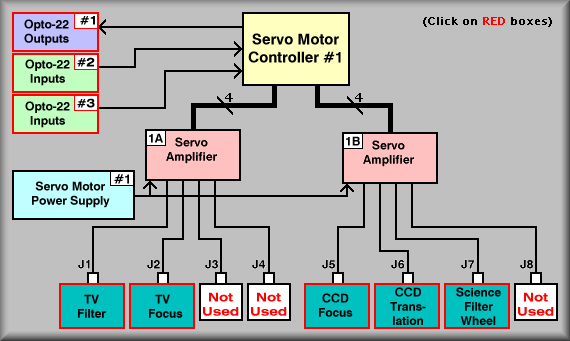

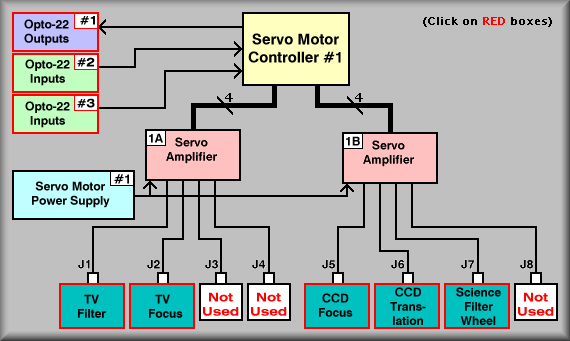

Galil Controller #1:

Extra info:

Simplified Drawing - Click on boxes for detailed description

To bring up the detailed description of any stage click on it's box in the

above diagram.

The above drawing illustrates the stages controlled by Galil controller number

1. The yellow block at the top, center of the diagram represents the Galil DMC-1580-72

Servo Motor Controller. The part number indicates that the unit is a 1500 series,

8-axis controller with an additional 72-bit I/O expansion box. To the right

of the controller block are the three I/O racks and below it are two Galil AMP-1140

servo amplifiers. Below the controller are the two AMP-1140 servo amplifiers.

The controller connects via three 50-pin ribbon cables directly to the Expansion

I/O. The expansion I/O consists of three banks of 24 bits. The first 24 bits

can be programmed to be either outputs or inputs. The other two banks are dedicated

as inputs. For our implementation, the first 24 bits are programmed as outputs.

This is done by setting the Galil variable CO to 7. Each bank of 24 bits leave

the Galil controller via a 50-pin ribbon cable. Galil has configured the I/O

pin assignments to match the Opto-22™ G4PB24 I/O rack. We have used these

components to simplify wiring of the instrument.

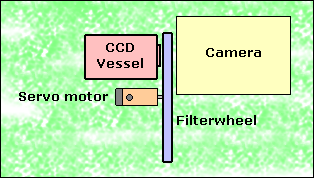

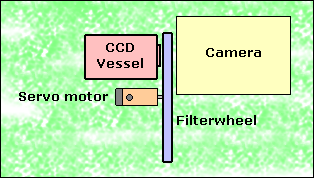

Below the yellow block are the two pink blocks

that represent the two Amp-1140's. Each amplifier can independently power up

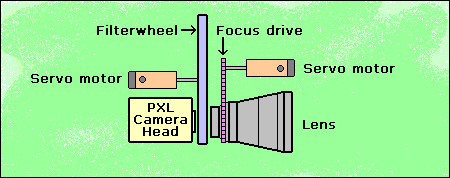

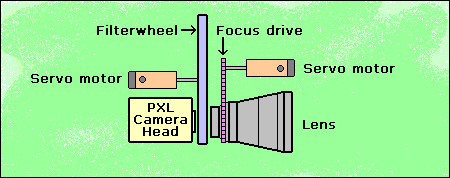

to four servo motors. In the case of amplifier #1A, only two stages are connected:

the TV Filter stage at J1 and the TV Focus stage at J2. These stages are mounted

in the front of the instrument with the Photronics PXL camera. The filter wheel

has eight positions and is normally loaded with 7 filters and an open position.

The TV Focus stage motorizes the focus ring on the Kodak 200 mm lens.

The Filterwheel Stage is an unconstrained stage, meaning that it does not have

forward or reverse limits. The stage is set by finding the fiducial to set the

zero point. The Focus Stage is a standard, constrained stage. It again uses

a fiducial for setting the zero point but also has three types of end of travel

limits: first is the software limit, then the primary hardware limit, and lastly,

the secondary hardware. The software should keep the stage from traveling past

the software limit. If it fails to stop the stage, the primary hardware limit

sends a limit tripped signal to the controller which should stop the motor.

Once the primary limit is violated the controller should only allow the stage

to move away from the limit. If both the software and primary limits fail, the

secondary limit interrupts the power to the motor. At this point, the stage

must be driven out of the limit by physically turning the motor shaft. See the

TV Filter and Focus

pages for more info on these stages.

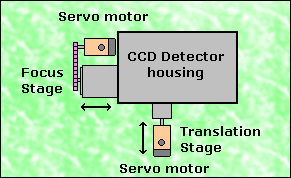

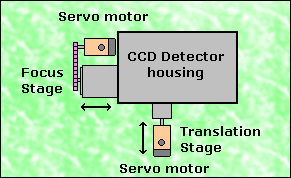

Amplifier 1B controls the CCD dewar focus and

translation stages along with the science filterwheel. Control of the two CCD

stages is unique in the instrument. Due to the small motion of these stages,

the limit switches that had to be used do not come in a 2PDT. Thus, the secondary

limits do not generate a input for the Galil controller. The stages both have

the usual software limits that should keep the stage from reaching the hardware

limits. They also have the primary hardware limit that tells the Galil controller

to stop motion (only) in that direction. The secondary limits, however,

are SPDT switches that are wired in series with the motor current. The difference

with these stages is that the controller does not receive the feedback that

it would get from a normal secondary limit. This is not critical in that the

stages would have to be backed out of the limit manually anyway.

The final stage on controller #1 is the Science Filterwheel

Stage. It is an unconstrained stage, meaning that it does not have forward or

reverse limits. The stage is set by finding the fiducial to set the zero point.

The filters are centered in the beam by moving a predetermined number of encoder

counts.

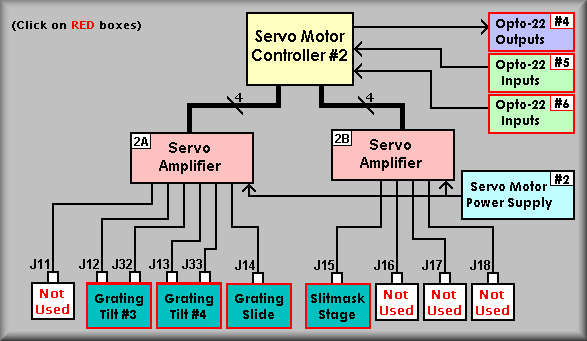

Galil Controller #2:

Extra info:

Simplified Drawing

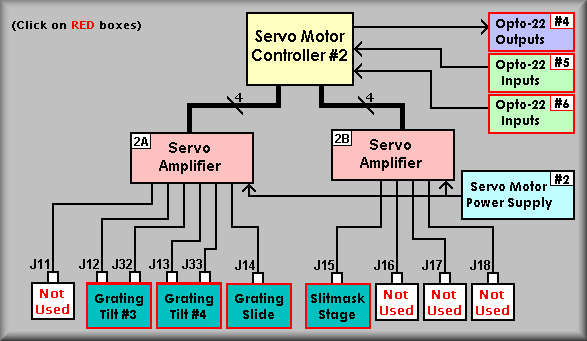

The above drawing illustrates the stages controlled by Galil controller number

2. The yellow block at the top, center of the diagram represents the Galil DMC-1580-72

Servo Motor Controller. The part number indicates that the unit is a 1500 series,

8-axis controller with an additional 72-bit I/O expansion box. To the right

of the controller block are the three I/O racks and below it are two Galil AMP-1140

servo amplifiers. Below the controller are the two AMP-1140 servo amplifiers.

The controller connects via three 50-pin ribbon cables directly to the Expansion

I/O. The expansion I/O consists of three banks of 24 bits. The first 24 bits

can be programmed to be either outputs or inputs. The other two banks are dedicated

as inputs. For our implementation, the first 24 bits are programmed as outputs.

This is done by setting the Galil variable CO to 7. Each bank of 24 bits leave

the Galil controller via a 50-pin ribbon cable. Galil has configured the I/O

pin assignments to match the Opto-22™ G4PB24 I/O rack. We have used these

components to simplify wiring of the instrument.

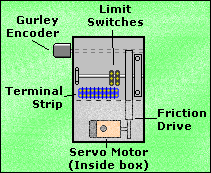

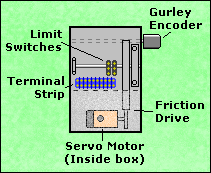

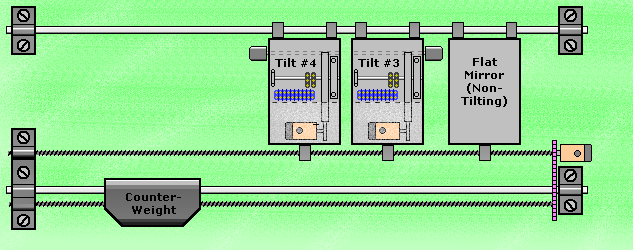

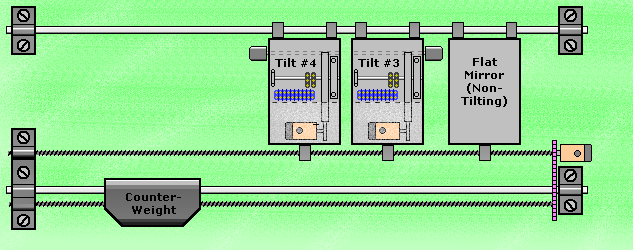

Below the yellow block are the two pink blocks

that represent the two Amp-1140's. Each amplifier can independently power

up

to four servo motors. Amplifier #2A has the following stages connected: J12

and J32 are connected to Grating Tilt mechanism #3, J13 and J33 connect to

Grating

Tilt mechanism #4, and J14 connects to the grating select stage. Connectors

J32 and J33 connect to each stage's auxiliary encoder (Gurley Precision model

8335-11250-CBSA). The secondary encoders are used to position the stage while

the primary encoders are used to close the servo loop. These stages are wired

as normal constrained stages with the addition of the auxiliary encoders. Again,

the constrained stage has software, hardware primary, and hardware secondary

limits. The software limit should stop the tilting motion of the grating when

encountered, the primary limit connects to the Galil controller limits that

should stop any additional motion in the direction of the limit, and the secondary

limit removes power to the motor in case both other limits fail.

|

|

|

|

Grating Tilter #3

|

Grating Tilter #4

|

The Grating Select stage is a normal constrained

stage as above. This stage moves the select grating tilt mechanism into the

light path at the grating box. Once there, a set of 5 pneumatic clamps lock

the grating into place. In addition to the normal stage limits and home

fiducial, the grating select stage uses an extra optical-slotted switch (PRM)

to define the position of the selected grating. Under software control, the

select mechanism moves the grating tilt mechanism into rough position for clamping.

Once there, the PRM is activated and the select stage does a homing routine

to the edge of a blocking flag attached to the grating cell. Once that is done

the clamps are activated in a sequence that helps make the final clamping position

as accurate as possible.

Grating Select Stage

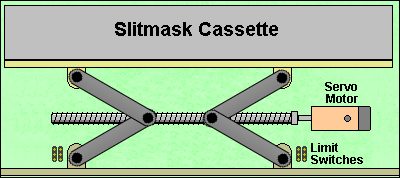

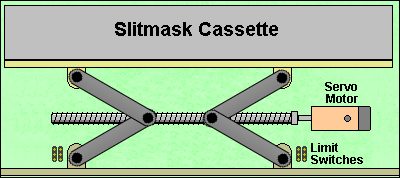

Amplifier #2B controls only the Slitmask stage via J15.

The Slitmask stage is really a combination of a constrained motor stage and

a highly specialize pneumatic stage. The servo motor runs what amounts to a

scissors jack that positions the slitmask cassette to discrete positions for

each of the slitmask slots. Again, the constrained stage has software, hardware

primary, and hardware secondary limits; the software limit should stop the scissoring

motion of the stage when encountered, the primary limit connects to the Galil

controller limits that should stop any additional motion in the direction of

the limit, and the secondary limit removes power to the motor in case both other

limits fail.

Slitmask Scissors Stage

Sheet 2:

Simplified Drawing

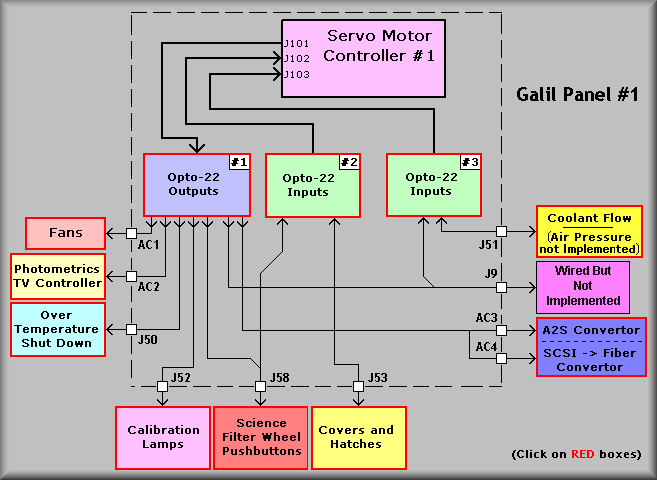

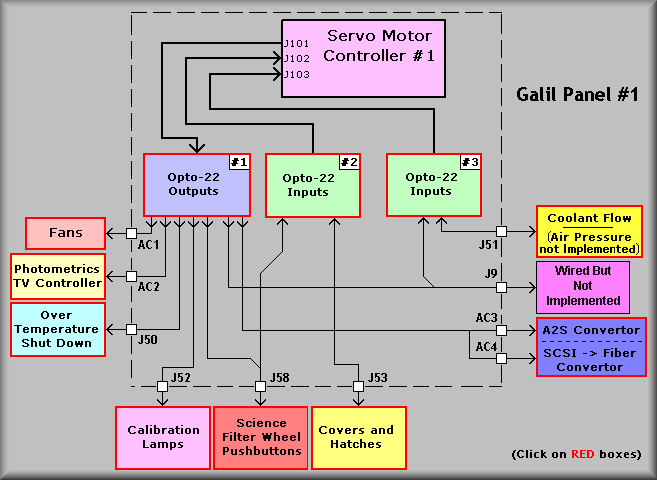

Galil Controller #1 Expansion I/O:

The above drawing shows the connections and cabling for the expansion I/O for

Galil Controller #1. Note that the first I/O block is set for outputs and that

blocks 2 and 3 are inputs. The pinouts for the Galil cables are :

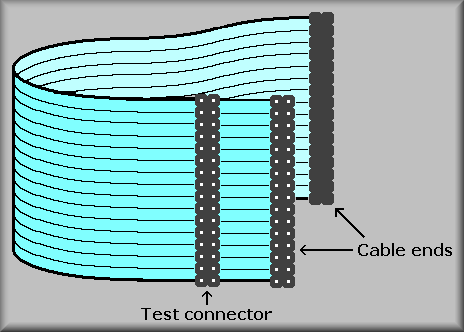

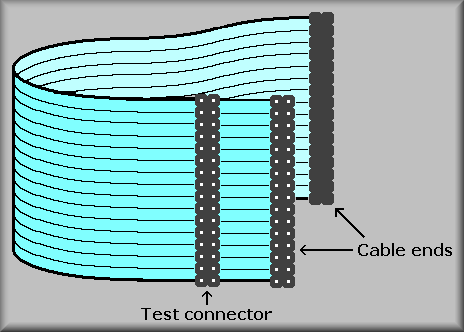

Also note, each of the Galil I/O cables has been fitted with

a spare IDC connector located near the controller end of the cable. This provides

a convenient place to probe the I/O signals when troubleshooting.

Connectors are shown at the edge of the dashed line that represents the controller

panel. These connectors allow the controller panel to be removed and reconnected

by merely disconnecting the I/O, stage cables, communication, and power cables.

The AC1 through AC4 connectors are AC outlets. Their power is controlled via

Opto22 AC output relays.

AC1 is controlled by software and connects to the cooling

fans. The software monitors the temperature within the electronics ring via

a solid-state sensor and uses the fans to keep the temperature within the

ring at about 40° F.

AC2, AC3, and AC4 are used to control the sequence in

which the guide TV camera powers up. To get the camera system to come up reliably,

the power should be turned on in the following sequence:

-

Fiber-to-SCSI convertor

-

AIA-to-SCSI convertor

-

Camera controller

Connector J50 is wired to the EL-3003 AC power controller. This connection

allow the Galil controller software shut down the orange circuit power if the

temperature become too hot. The controller's signal is wired in parallel with

a 85° F thermostat that will force the AC power off if for some reason the

Galil becomes disabled. A quick note: if the thermostat has a lot of histerysis,

if it does trip off the AC, the thermostat will have to cool down before it

will let the power be reapplied.

Connector J52 is the main control cable for the calibration lamp system.

It contains the AC lines that are used to apply power to the various lamp power

supplies.

Connector J58 is the cable for the Filter Wheel pushbutton Station. The

pushbutton station provides local control at the filterwheel for use when loading/unloading

filters.

Connector J53 connects to the hatches that give access to the inside

of the barrel. These are the Man Hatch, Dewar Hatch #1, and Dewar Hatch #2.

The wiring allows the control computer identify which hatch is causing the instrument

to not rotate.

Connector J51 is wired to the Potheus Flow meter. The Photometrics TV

system is powered only when the coolant is flowing.

Simplified Drawing

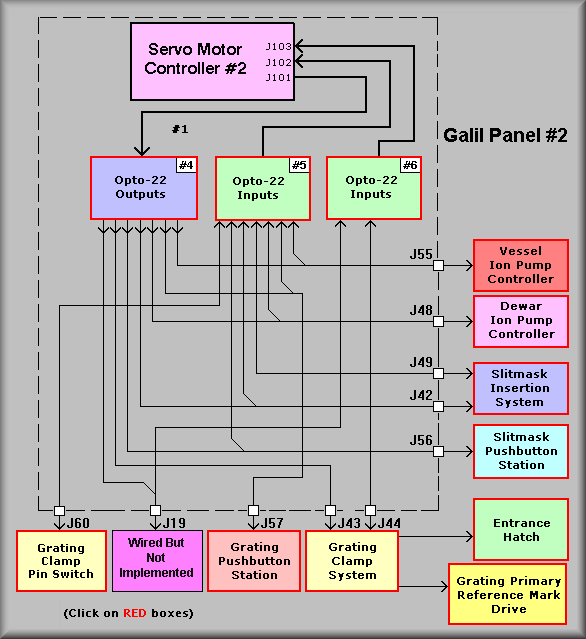

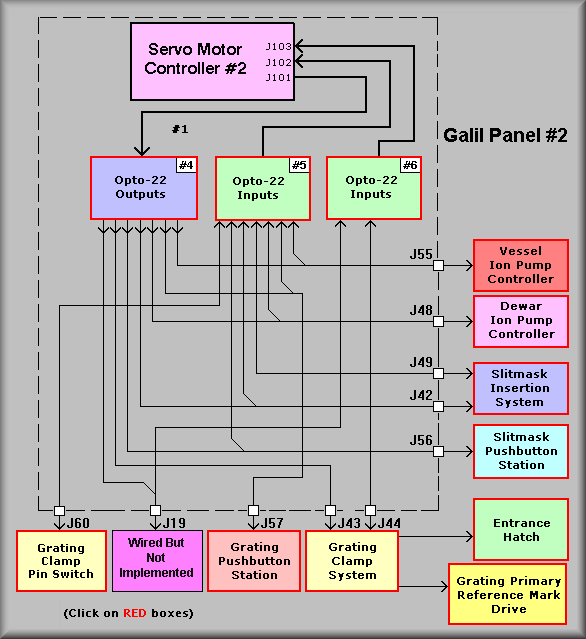

Galil Controller #2 Expansion I/O:

The above drawing shows the connections and cabling for the expansion I/O for

Galil Controller #1. Note that the first I/O block is set for outputs and that

blocks 2 and 3 are inputs. The pinouts for the Galil cables are :

Also note, each of the Galil I/O cables has been fitted with

a spare IDC connector located near the controller end of the cable. This provides

a convenient place to probe the I/O signals when troubleshooting.

Connectors are shown at the edge of the dashed line that represents the controller

panel. These connectors allow the controller panel to be removed and reconnected

by merely disconnecting the I/O, stage cables, communication, and power cables.

The AC1 through AC4 connectors are AC outlets. Their power is controlled via

Opto22 AC output relays.

Connector J60 is wired to the Grating Clamp Pin switch.

The pin is actuated by grating clamp #2. As it clamps, the pin is pushed into

the switch which tells the software that the grating is properly clamped.

Connector J57 is the cable for the Grating Pushbutton Station. The

pushbutton station provides local control at the grating select stage for

use when loading/unloading gratings.

Connector J43 is wired to the grating clamp solenoids. It provides

the signals to activate/deactivate the grating clamps. The grating clamp system

is a series of four clamps, numbered 1, 2, 4, 5, (solenoid 5 actually controls

2 clamps) that push the selected grating slider into position on the grating

box. The entrance hatch solenoid is also located on the grating solenoid panel

and is wired via J43. Lastly, the signal that powers the grating system Primary

Reference Mark sensor is wired through this cable to the solenoid panel where

it branches off to the PRM.

Connector J44 is the grating clamp and entrance hatch cylinder limit

switch cable. Each of the five clamp and two hatch cylinders have magnetic

reed limit switches at both ends of travel. These signals provide feedback

to the control electronics of the actual position of each of the cylindars.

Connector J55 is wired to the CCD coolant vessel Ion Pump Controller.

The cable provides remote operation of the controller by providing an output

that effectively closes the start switch on the controller, and a AC power

on input, a front panel selector switch monitoring input, and an analog input

to read the ion pump current.

Connector J59 is wired to the CCD Dewar 'Chamber" Ion Pump Controller.

The cable provides remote operation of the controller by providing an output

that effectively closes the start switch on the controller, and a AC power

on input, a front panel selector switch monitoring input, and an analog input

to read the ion pump current.

Connector J49 is wired to the Slitmask stage. It contains all of the

monitoring signal associated with the insertion and removal of the slitmasks.

It does not, however, contain the scissors stage wiring. That is wired via

the stage connector J15.

Connector J42 is also wired to the Slitmask stage. It contains the

control and monitoring signals for the actual solenoid that drives the Bimba

slitmask insertion cylinder.

Connector J56 is the cable for the Slitmask Pushbutton Station. The

pushbutton station provides local control at the slitmask select stage for

use when loading/unloading slitmasks.

Sheet 3:

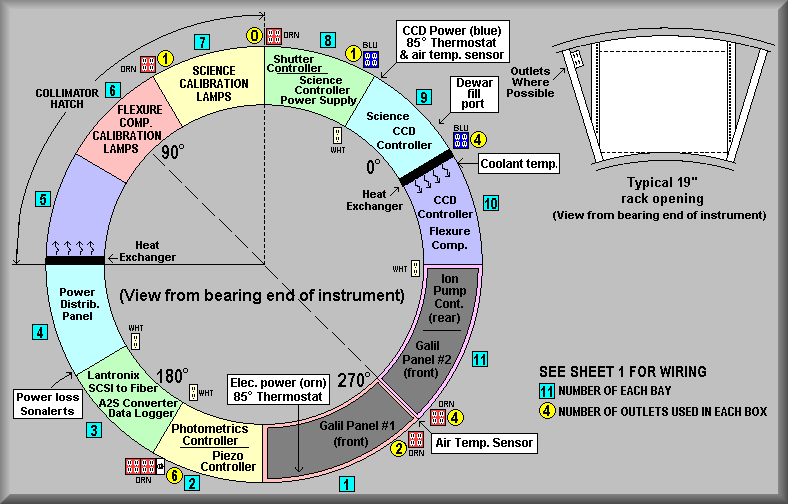

This sheet is a graphical representation of the barrel electronics ring.

Electronics

Ring Equipment Locations |

| Bay Number: |

|

Equipment |

| |

|

Front |

Back |

| 1 |

|

Galil controller #1 |

Calibration lamp interlock box |

| 2 |

|

Photometrics TV camera controller

Tent Mirror Piezo actuator controller |

N/A |

| 3 |

|

Lantronix Terminal Server

SCSI-to-Fiber Convertor

AIA-to-SCSI Convertor

HP Datalogger - Temeratures |

N/A |

| 4 |

|

AC Power distribution panel |

N/A |

| 5 |

|

Empty |

N/A |

| 6 |

|

Flexure Compensation System lamps |

N/A |

| 7 |

|

Calibration lamp power supplies |

N/A |

| 8 |

|

Science CCD controller power supply |

Shutter controller |

| 9 |

|

Science CCD controller |

N/A |

| 10 |

|

FCS CCD controller |

N/A |

| 11 |

|

Galil controller #2 |

Ion Pump controllers |

Troubleshooting:

The controller also connects to the servo amplifiers via four flat ribbon cables

each. These carry the signals between the controller and the amplifiers. The

cables carry the motor control and enable signals plus limit switch and miscellaneous

signals. To aid in troubleshooting, we have added extra ribbon cable connectors

to the cables that allow a technician to probe the individual signal lines with

a meter or oscilloscope.

The following table contains links to pinouts for the ribbon cables that connect

the DMC-1580 controller to the Amp-1140 amplifiers. The Jn and JDn

cables do not always carry the same signal on the same pins. The is mostly,

but not exclusively, true on J5 and JD5, the I/O cable. The last three cables,

the Galil I/O cables J1 - J3, are the cables that connect from the Galil 72-bit

I/O board to the Opto-22 relay racks.

Galil controller interconnect cable pinouts

![]() EL-3001

EL-3001