Barrel Stage Wiring

The barrel stage wiring section of this manual contains descriptions of the individual stage wiring for the barrel portion of the DEIMOS Spectrograph. It corresponds to the Barrel Stage Wiring tab in the electronics schematics binder.

TV Filter Wheel Stage,

![]() EL-3050

EL-3050

Schematic: schematics/TVFILTER.sch.pdf

Page last updated: June 26, 2002

Simplified Drawing. For complete schematic click on schematic button above.

1. DC servo motor with integral optical disc encoder 2. Slotted optical switch that is used as the fiducial

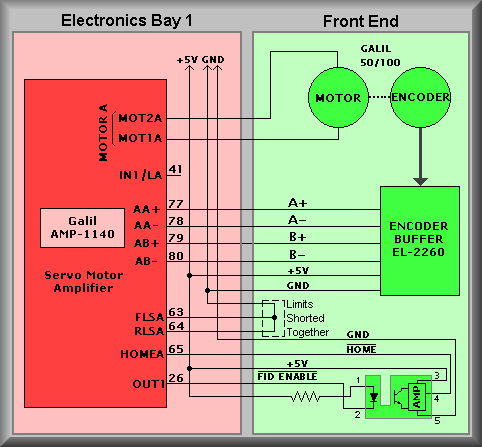

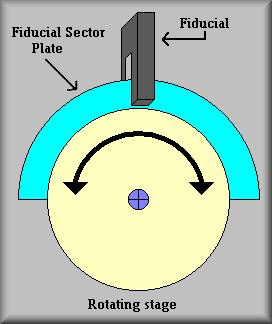

The motor/encoder is from Galil and is the same basic motor that has been used both in the ESI and HIRES instruments. The Galil part number is 50-1000. The motor is rated at 30 oz-in (0.21 Nm) of torque, 3750 rpm, and has a 1000 line per rotation encoder. The encoder supplies A and B phase signals in quadrature and thus is decoded to 4000 counts per revolution. The optical slotted switch is an OPB970T55 component from Optek (at one time TRW). The TV filter wheel is connected to channel A of controller #1 via the Galil AMP-1140 module. The connections shown on the amplifier module refer to the screw terminals thereon. For instance, the encoder output connections are made to screw terminals 77-80. The signal names on the amplifier module reflect the A+ and A-, and the B+ and B- phases of the encoder. The second letter, A, refers to the controller channel to which the signals are connected. At the bottom of the amplifier block are the connections to the HOME fiducial. The signal OUT1 is used to enable the slotted optical switch, or the fiducial. A clear bit instruction, CB1, pulls the output line low causing the emitter section of the fiducial to turn on which illuminates the receiver portion of the switch. With this done, the stage can be moved to find the edge of a blade that is attached to the stage. Because the blade is made to cover the slotted switch for 180° of the stages rotation, the software can determine which direction to move the stage to get to the correct edge of the blade to 'zero out' the stage. The intervening connectors for the stage have been left off of the drawing for By executing it's homing routine, the software can set the stage to a known zero point and subsequently to any of the filters positions which are a fixed distance from the HOME point.

Troubleshooting:

If the TV Filter stage will not move there are several steps to be taken to isolate the problem:

1. Visual Inspection: Remove the appropriate hatch(es) to gain access to the TV camera stages. Looking into the stage check that the pink drive belt hasn't broken or come off of it's pulleys. Look into the limit switch area to determine that the switches and the wiring is intact. Check to see if the limit actuator is positioned within the limits. Finally, with the servo power off, check to see that the filter wheel rotates freely by manually rotating the it.

2. Cables: The first thing to look at is the cabling. Start at Galil controller panel #1 and check that it's stage cable is connected to J1. (As this stage does not use an auxiliary encoder, there should be no cable connected to J21). Next, look at the EL-1236 interconnect box cables. It is located at the front of the instrument on one of the supports for the front bulkhead. It is labeled TV Filter. (Note: the TV Focus interconnect box is also located in this area.) The main cable comes into the box from the rear part of the instrument and connects to JB1. The connectors leaving the box on the other side are JB2, JB3, and JB6. JB2 is the motor power cable. If it is disconnected the secondary limit signal will float high telling the controller that the stage is in the limit and, of course, there will be no power to the motor. JB3 contains the connections for the primary limits and the fiducial. Because the TV Filter Wheel stage is an unconstrainted rotary stage, there are no primary limits. As shown in the diagram above, the two primary limit input lines are tied to ground at the stage. This causes the stage limits to become asserted if the cable is disconnected. Thus, if the cable were unplugged you would get a primary limit error, again because with the cable off the controller sees the forward and reverse primary limits as being made (i.e. the input floats high.) The last cable is the ribbon cable that connect the motor encoder to the controller. If this cable was off the controller would try to move the stage. The motor would start to turn but the encoder would not change. Because the software sets the OE (Off on Error) the motor will turn off as soon as it has moved a small way. This is the result of the error in commanded position versus actual position has grown larger then the ER error value.

3. Power Supplies: The next logical place to check is the power supplies.

The supplies in question are the 28V motor power, the 5V, +/-12V logic power,

and finally the power supplies in the Galil controller. First, open the necessary

covers on the electronics ring to gain access to Galil panel #1. The Logic Supply

+5V can be measured across the +5 and GND terminal strips TBA and TBB. The +28V

power supply can be measured across the two large large terminals on the Lambda

power supply. The trickiest to measure is the Logic Supply +/-12V supplies.

To get to the terminals of this supply the supply has to be removed from the

Galil panel. To do this, remove the AC power cord that supplies the panel (the

second power cord on the Panel plugs directly into the Galil controller and

needn't be unplugged). Next, locate and remove the clear plastic AC shield that

protects the AC input terminals of the logic supply. Remove the Allen head cap

screws that attach the Logic Supply to the Opto-22 relay rack support. Now lay

the supply out to where you can get to the +/-12V terminals with a meter and

carefully plug the AC power back in. Measure between the +12V terminal and any

GND terminal on TBB. Do the same for the -12V supply. On the Galil, extra connectors

have been crimped onto the ribbon cables that connect the controller to the

amplifiers. These connectors provide test points for all of the signals from

the controller, including the internal power supply lines. To measure the Galil

power supply insert probes into the following pins

Ground Pin 1 +5 volts Pin 59 +12 volts Pin 57 -12 volts Pin 58

4. Isolate the problem: Use a spare Galil 50/1000 motor to determine if the motor is being servoed. This can be done by connecting a spare motor via the motor/limit test cable as shown below. Connect the CPC connector to the stage interconnect box at JB3.

Motor Test Connector

Step 1: Stop dispatcher #1 and login to Galil controller #1:

Step 2: First, issue a MO (Motor Off) from the Galil command line. This will remove power from all motors if it is not already off. Disconnect the motor connector JB2 and the encoder connector JB6 from the stage interconnect box. Connect the Motor Test Connector's JB2 motor connector and JB6 encoder ribbon cable connectors. Now issue a SHA (Servo Here channel A) from the Galil command line. This should servo the motor and you should feel stiff resistance to rotating the shaft. If the motor runs away, remove motor power as above with the MO command, swap the red and black wires at the motor, and servo the motor again. Swapping the motor leads should ensure the motor runs the same direction as the encoder. If the motor runs away again the problem is likely that either 1) the EL-2260 Encoder Buffer has failed, 2) there is a problem in the Interconnect Box, or 3) there is a problem in the stage cable. If this is the case, next try inserting the spare EL-1236 Interconnect Box in place of the original and repeat the above test. If this test fails inspect the cable ends and pins for broken or bent pins. If the test motor servos but the stage motor doesn't, carefully check the wiring from the interconnect box to the motor. If the wiring looks OK, issue the MO command and reconnect the stage cables JB2 and JB6 to the interconnect box. Disconnect the red and black leads from the motor and connect them to the test motor. Issue the SHA command and again test the motor shaft for servo power.

Limit Test Connector

Step 3: Test the fiducial. First, enter the command: SB1. Now, issue the command TSA. Convert the hex number that is returned into binary to check the state of the HOME input. Bit position 2 should read as a 1. If not, look for short to ground on the HOME signal wire. If it does read as a 1 then issue the command CB1. This turns on the emitter section of the optical slotted switch. With the slot not blocked, issue the TSA command again. This time bit position 2 should read as a 0. If not, look for a short to ground on the HOME signal wiring. Now, block the slotted switch and issue the TSA command once again. Bit position 2 should read as a 1 once again.

Step 6: If the stage is still not functioning correctly try isolating the main stage cable by plugging the stage test cable into J2 of Galil controller #1. Plug the other end into the spare EL-1236 Interconnection box. Plug in both the Motor Test connector and the Limit Test connectors into the interconnection box and start back at step 2 above

Step 7: After replacing any defective components restart the above procedure at step 2.

Step 8: Logout and restart the dispatcher:

To exit:<Control> ] (control key and right bracket key)

telnet> quitRestart Dispatcher:

deimos start dispatcher2.1